Solution processed multilayer optical elementsWe have fabricated distributed Bragg reflectors and a Fabry-Perot microcavity using inorganic-based solution depositon of dielectric materials. This process uses only inorganic-based precursors, for which the small particle size and lack of undesirable species enable the production of high purity, dense, smooth films at modest temperature. The multilayer devices are made from high-index TiO2 and low-index aluminum phosphate (AlPO). Alternating λ/4 layers of AlPO and TiO2 were deposited by spin coating and were polymerized for 1 min at 200C on a hot plate. The fabrication was completed with a furnace anneal in air at 300C for 1 hour. The solution process was developed in Prof. Keszler's laboratory (OSU Chemistry). References: "Low temperature, solution processing of TiO2 thin films and fabrication of multilayer dielectric optical elements," K. Jiang, A. Zakutayev, J. Stowers, M. D. Anderson, J. Tate, D. H. McIntyre, D. C. Johnson, and D. A. Keszler, Solid State Sci. 11, 1692-1699 (2009). "Solution-processed multilayer dielectric optical elements," A. Zakutayev, K. Jiang, J. Stowers, M. D. Anderson, J. Tate, D. A. Keszler, D. C. Johnson, and D. H. McIntyre, Micro-Nano Breakthrough Conference, Portland, Oregon, September 21-23, 2009. "Low-temperature, solution-based processing of TiO2 thin films; Fabrication of dielectric mirrors and microcavities," K. Jiang, A. Zakutayev, J. Tate, D. McIntyre and D. Keszler, Fall Meeting of the Materials Research Society, Boston, Massachusetts, 1-5 Dec, 2008. |

|

|

|

|

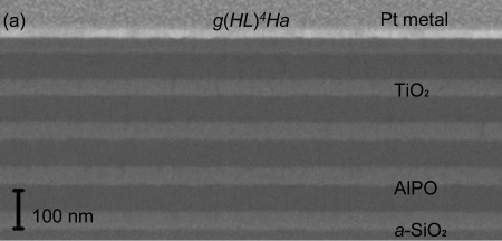

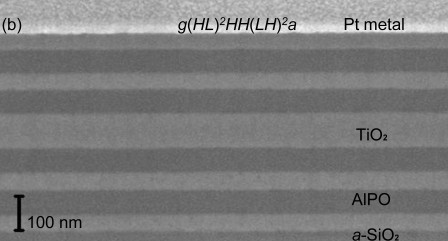

The multilayer elements have a general structure of g(HL)MHa, where g and a refer to the glass substrate and airrespectively , H and L refer to high- and low-index layers respectively, and M is the number of repeats of an HL unit. The interfaces of the Bragg reflectors (a) and the microcavity (b) are smooth and the layers are uniform across the full investigated length. Corresponding average thicknesses of the TiO2/AlPO layers are 46/70 nm for the Bragg mirror and 52/73 nm for the microcavity (not including the defect layer). This method gives superior control over the individual layer thickness and the uniformity. |

|

|

|

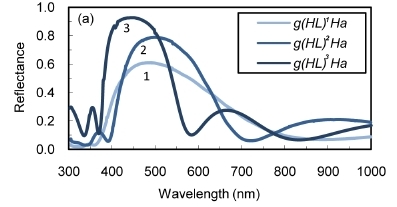

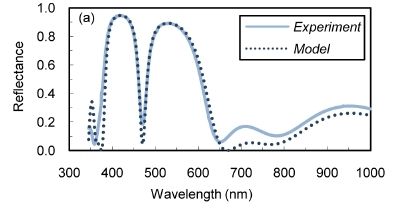

| The wavelength corresponding to the reflection maximum of the high reflectivity dielectric mirror is determined by the layer thicknesses and the indices, while the maximum reflectivity is determined by the index difference and the number of layers (M). We have achieved a maximum measured reflectivity of 64%, 83%, and 92% for M = 1, 2 and 3, respectively. The maximum reflectivity occurs at about 475 nm. These results agree well with our theoretical models, as does the polarization dependence of the reflectivity. | |

|

|

|

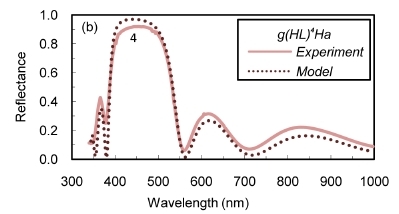

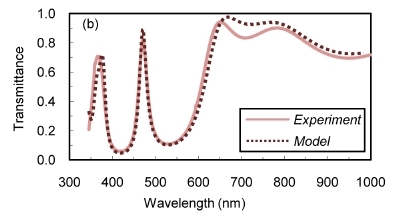

The optical microcavity has the form g(HL)2HH(LH)2a, where the two interior high-index layers form a single half-wavelength spacer or defect. The reflectance spectrum has a minimum at the resonant wavelength = 470 nm, while the transmittance spectrum displays a corresponding maximum at the resonance. The reflectance and transmittance at the resonant wavelength are 18% and 82%, respectively. The width (FWHM) of the reflection resonance is Δλ = 24 nm, which corresponds to a quality factor Q = λ/Δλ = 20. The measured quality factor compares favorably with a model value of Q = 24. |

|